Machines

Blow Molding Machines

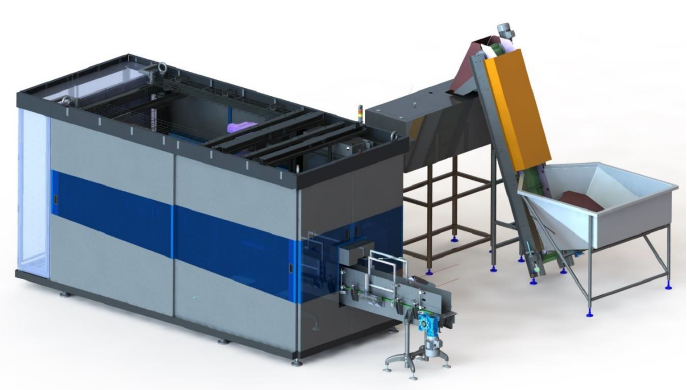

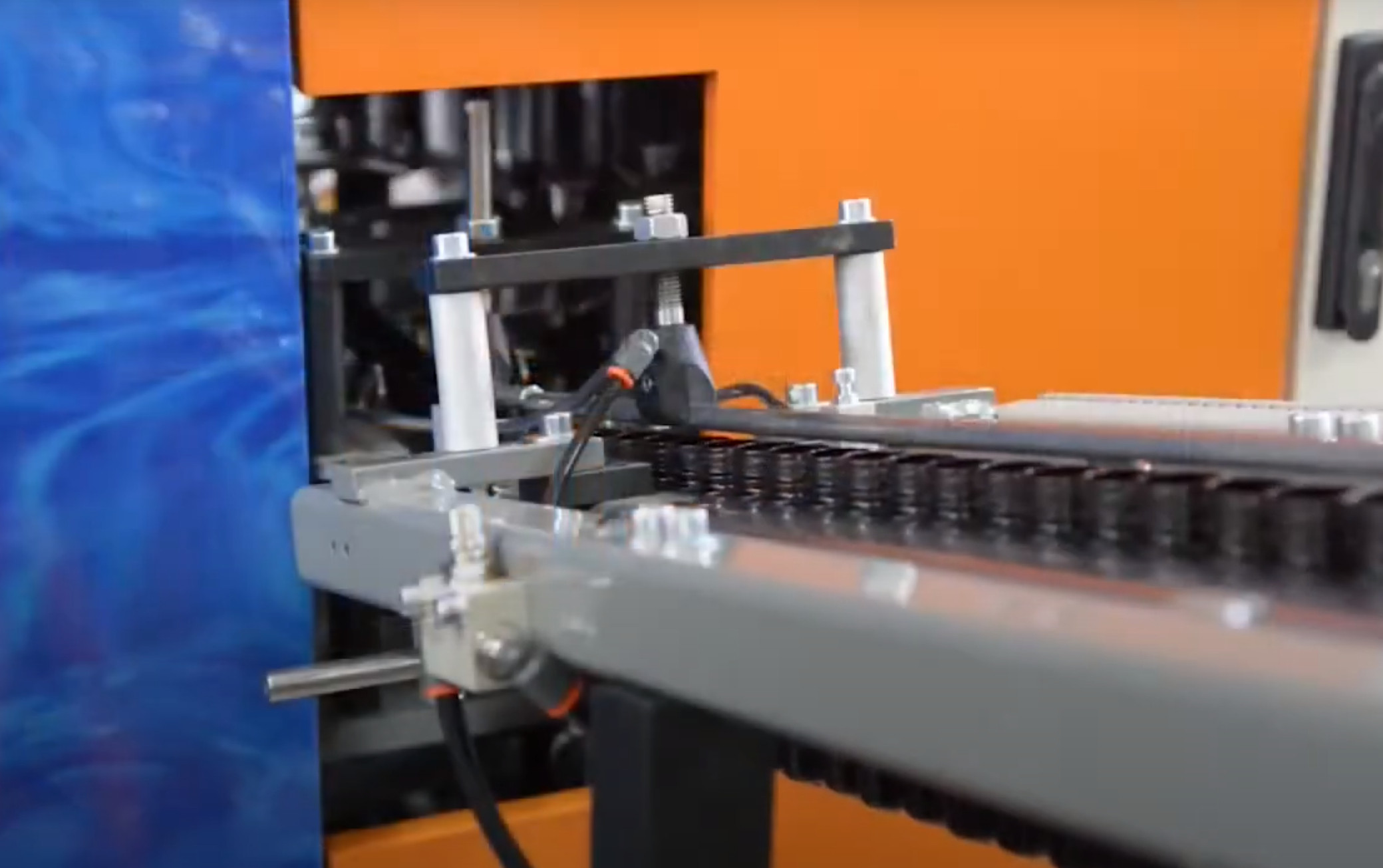

SynTec HS is a linear stretch blow moulding machine for production of PET bottles. World standard up-to-date technical solutions are used in the design of the machine, with elements from first-class manufacturers. The core of the blowing process is a high-quality set of valves for precise control of the process.

Our machines are manufactured under the control of qualified and skilled personnel, leading to a well-rounded and highly capable machine.

Depending on the final product (shape/size/weight) the machines can reach up to 98% of efficiency, a speed of up to 16.000 bottles per hour and a low energy consumption.

Different requirements like large bottles, oval bottles, hot filled bottles, very small bottles and standard bottles for daily use will be covered by the diverse capabilities of Syntec Series blow molding machines.

The Syntec HS series provides a full list of standard and optional solutions of our Powersave program, which aims to decrease power consumption by making the blow molding process more efficient.

Please see to our sales department for detailed technical data or a personalized quotation!

Filling Machines

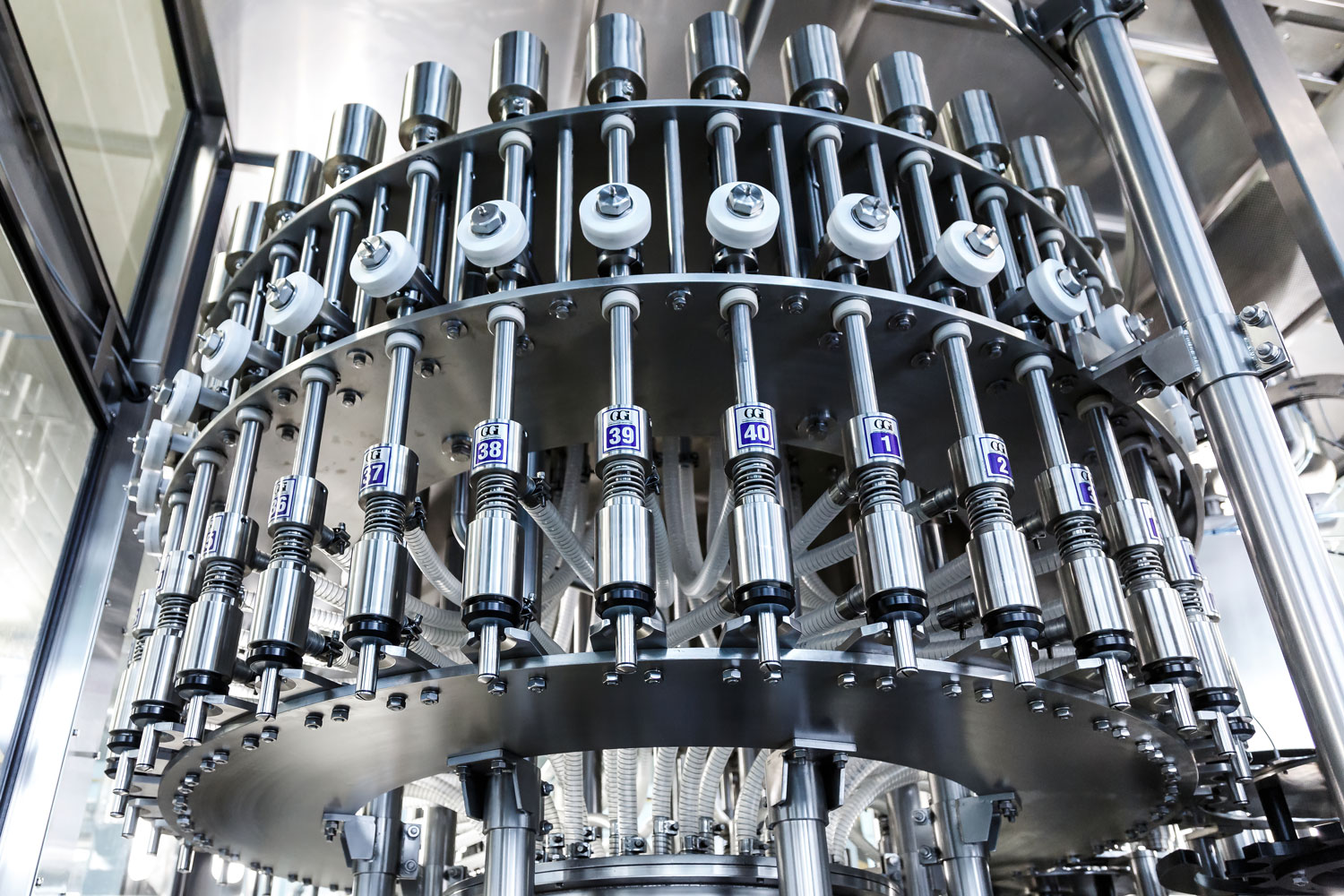

The TriaTec machines are distinguished between isobaric and gravimetric filling machines machines. Gravimetric is a process used for the filling of non-carbonated drinks whereas isobaric is used for the filling of carbonated soft drinks.

Both methodes are cabable of a production speed between 4.000 and 50.000 bottles per hour. The final speed is dependant on the bottle size and configuration of the machine.

The standard configuration can fill bottles from 0, 2 all the way up to 2,5l. We also offer special configurations, which can reach a filling capacity of up to 10l. To achieve this, the machines are equipped with 12 to 72 filling nozzles, which are made of 316l stainless steel.

The filling is done by electronic valves, which can be adjusted depending on the type of product and the customer´s needs.

Gammagroup can provide a suitable PREMIX to enable the filling of carbonated drinks.

The machines can handle all kinds of closures such as plastic screw caps or pressure caps.

All machines are manufactured to fulfil the highest technological standard, comply with the latest German industrial standards (DIN), are CE certified and CIP suitable to reduce maintenance requirements.

Please see to our sales department for detailed technical data or a personalized quotation!

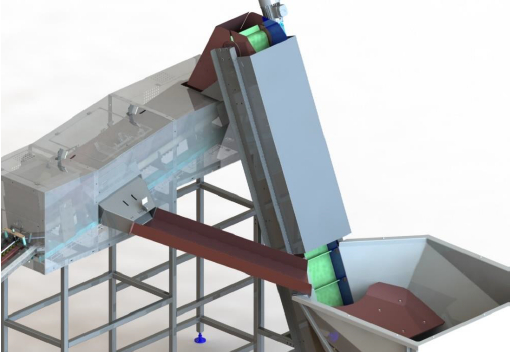

To simplify the production, we offer the inclusion of a preform unscrambler in our machines, which automatically feeds the blow molding machine with preforms during the blowing process.

This is used for stabilization and acceleration of the production process by removing unwanted blockages in the transfer of preforms to the blow molding machine. This way we can help to fully automize the production process right from the beginning of the line.

Please see to our sales department for detailed technical data or a personalized quotation!

Palletising System

Gammagroup offers a wide range of palletising systems with a selectable infeed speed and different accesses for loose bottles and packaging layers.

Our palletizing systems can handle cans, jars, bottles, cartons, bundles, and boxes. The main advantages of the systems are:

- Robust construction

- High-reliability

- Constant repeatability of the production cycles

- High speeds

- Easy maintenance

The palletizing systems are automatically equipped with a carton or bundle input from above or below.

In the optional multi-pallet version, it is possible for the system to separate the finished products from various production lines on different pallets.

The machine is designed to allow the installation of a shrink wrapper, to simplify the process of transportation of the pallets.

Please see to our sales department for detailed technical data or a personalized quotation!

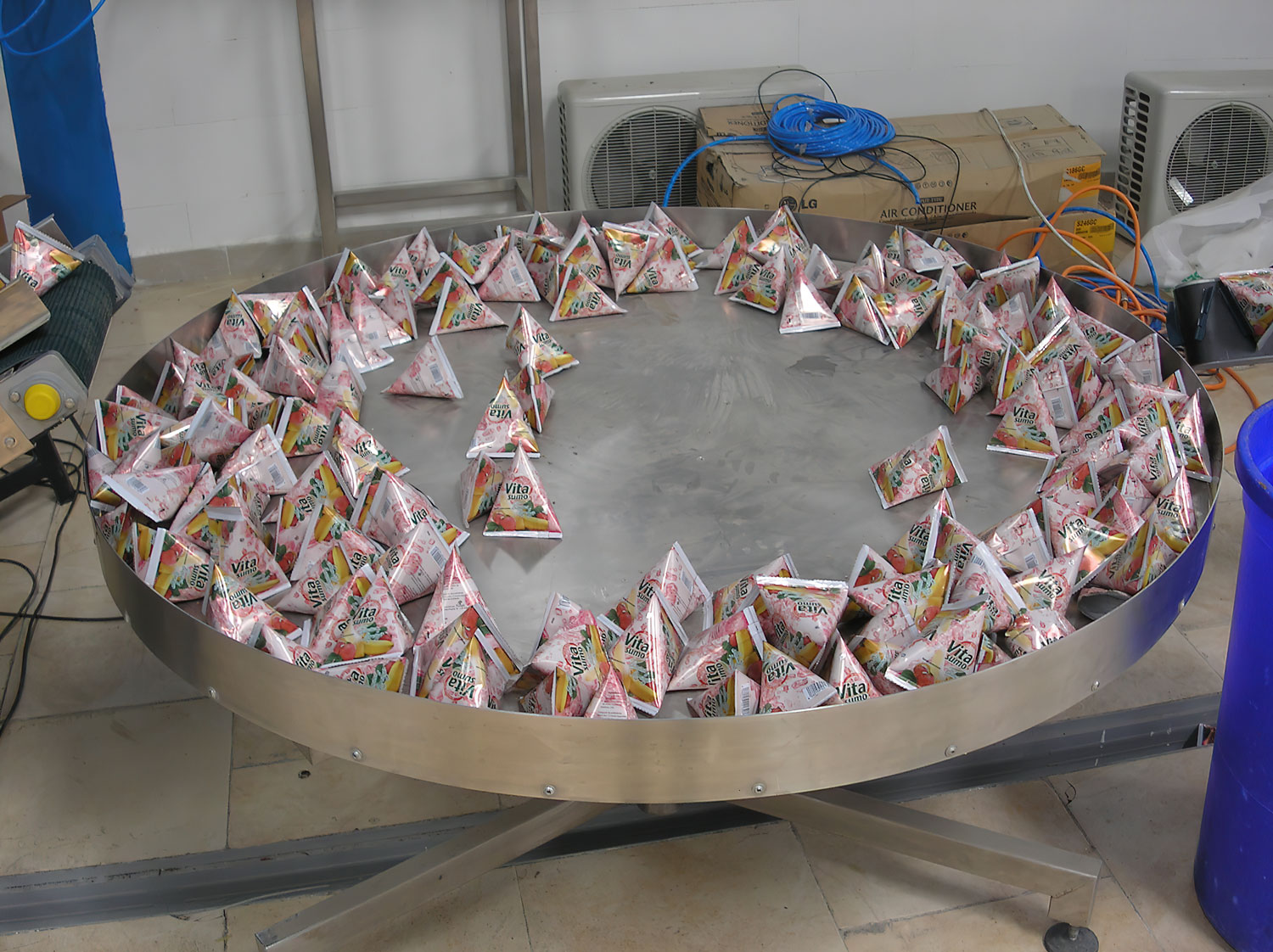

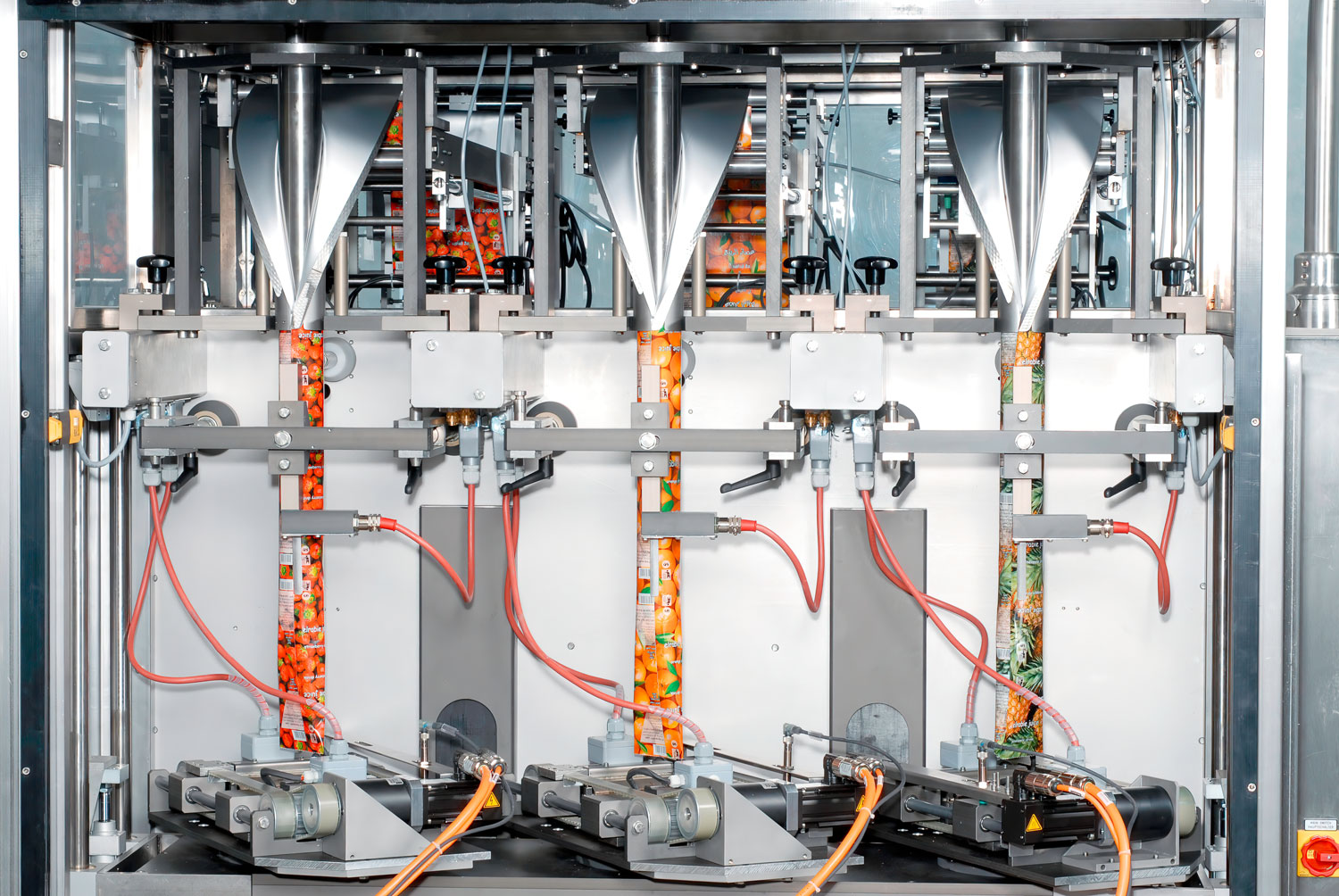

Twistpack Line

A common alternative to the non-aseptic packaging machine is the Twist Pack machine. This is particularly suitable for filling non-carbonated soft drinks and all pasty liquids in the food sector such as mayonnaise, ketchup et cetera. Another area of application is the packaging of solids such as sweets and chocolate lentils.

The capacities of the machines are in the range of 2,500 – 8,000 packs per hour, depending on the version of the machine and the type of product.

Please see to our sales department for detailed technical data or a personalized quotation!

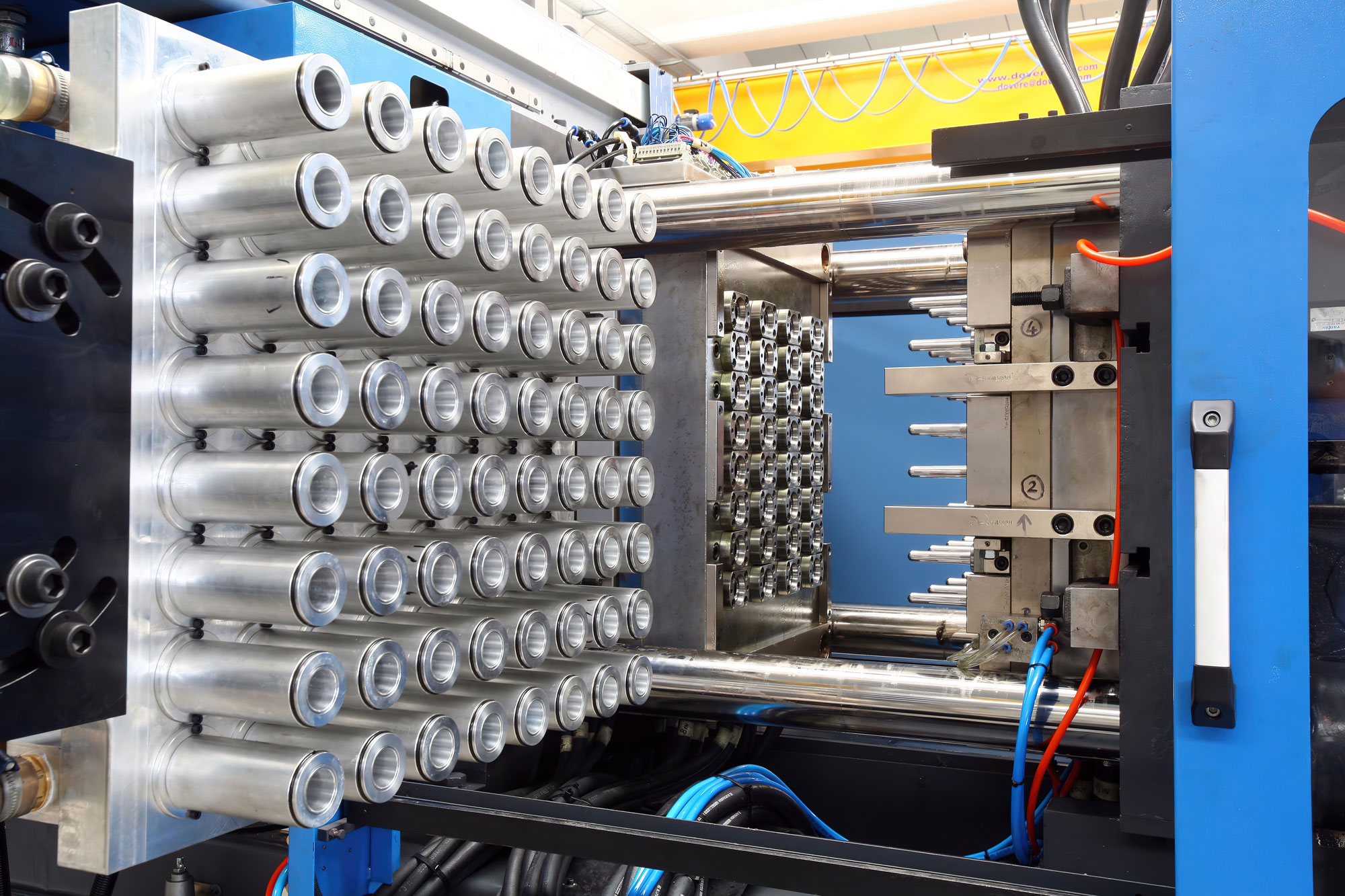

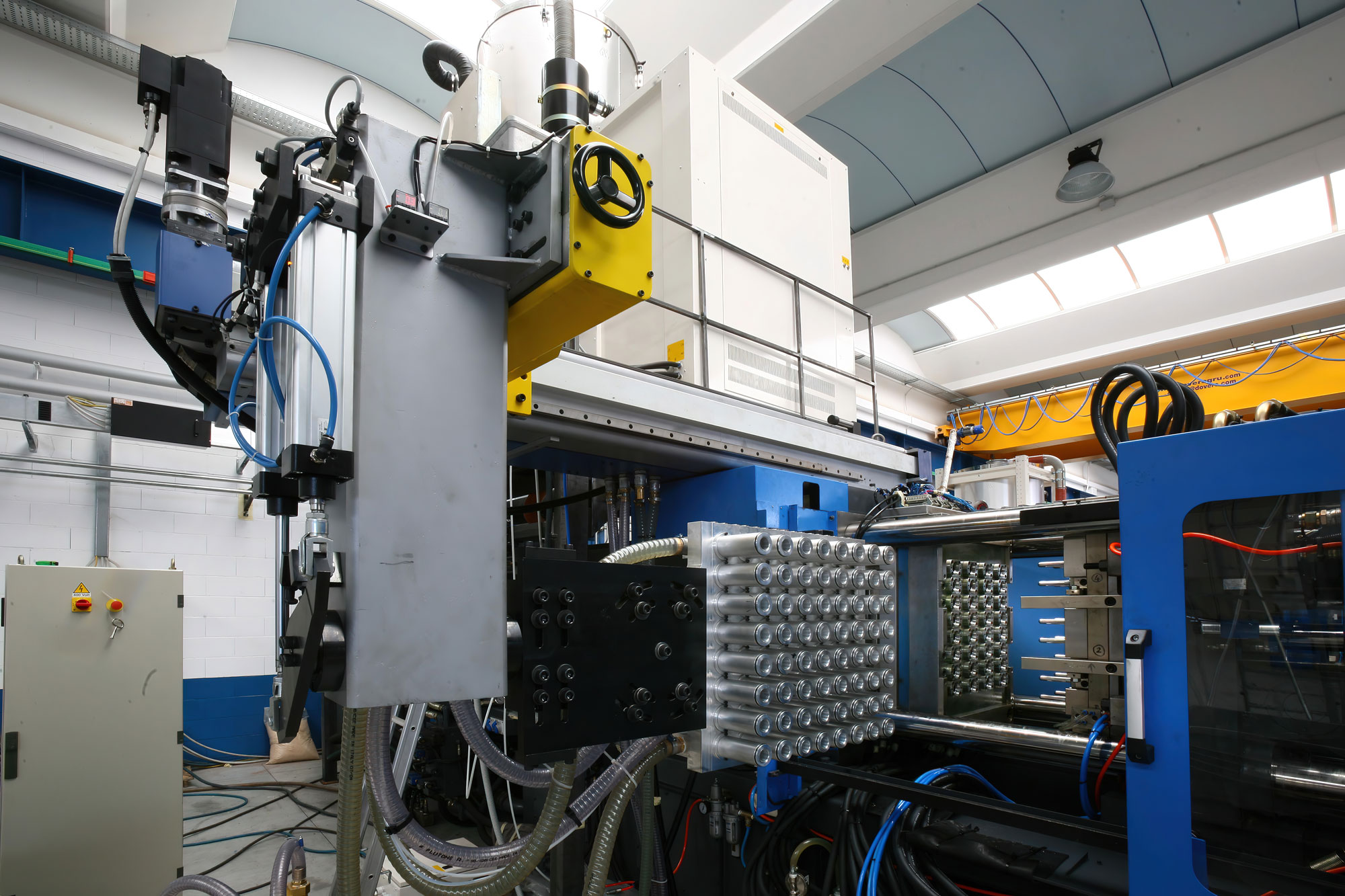

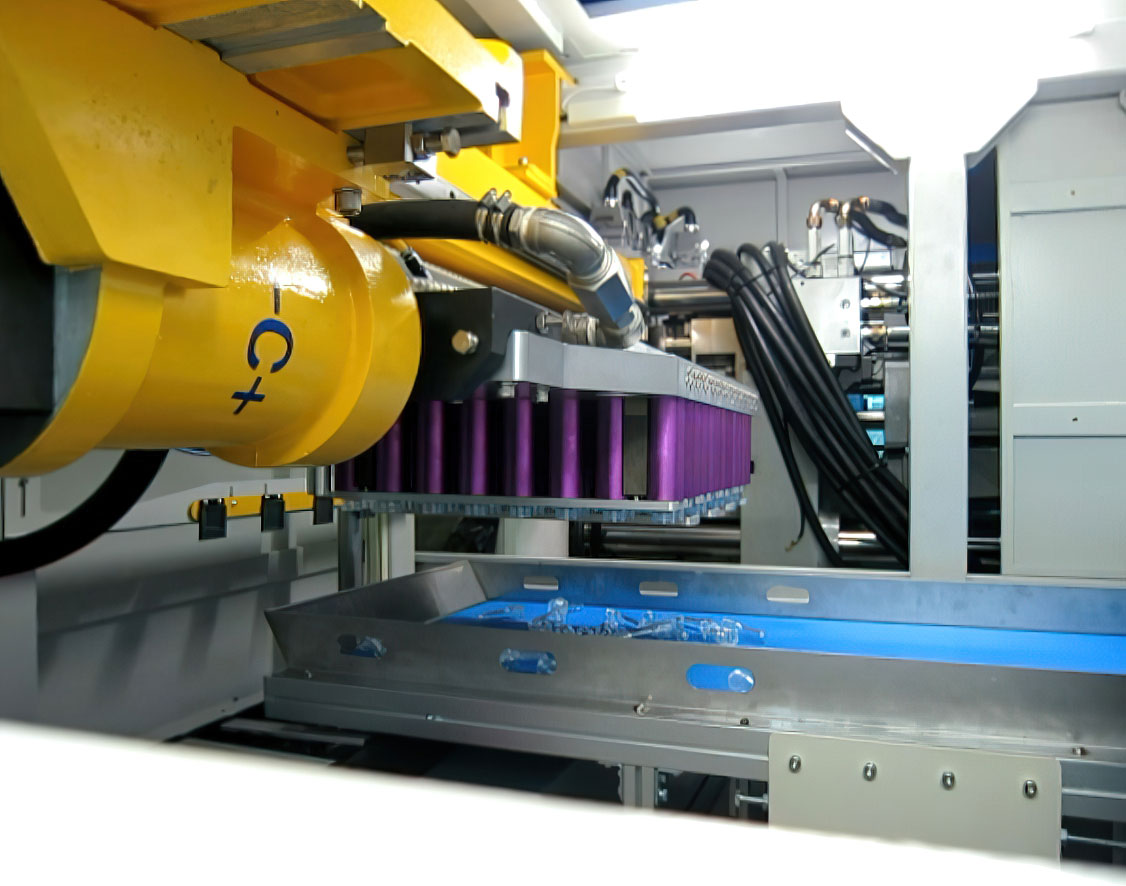

The injection molding line comes with:

- A two-level version which is available to guarantee fast and accurate spraying

- An injection unit matched to the application

- 24 – 48 Cavities

- A high-performance potential

- Integrated raw material treatment

- Reliable cooling, due to the integrated robot

- A robust and reliable construction

- Optimal energy efficiency

- The highest precision and repeat accuracy

- Maximum economic efficiency

- Minimum costs of materials

- The shortest cycle times

- The highest component quality

- The possibility of an electrical closing unit

Please see to our sales department for detailed technical data or a personalized quotation!